-

Bruno NascimentoTerima kasih atas bantuan dan dukungan yang terus menerus dalam menyediakan produk berkualitas tinggi dan terjangkau.

Bruno NascimentoTerima kasih atas bantuan dan dukungan yang terus menerus dalam menyediakan produk berkualitas tinggi dan terjangkau. -

Ehsan SalmariTanggapan yang cepat dan sikap profesional membuat kerja sama kami lebih lancar!

Ehsan SalmariTanggapan yang cepat dan sikap profesional membuat kerja sama kami lebih lancar!

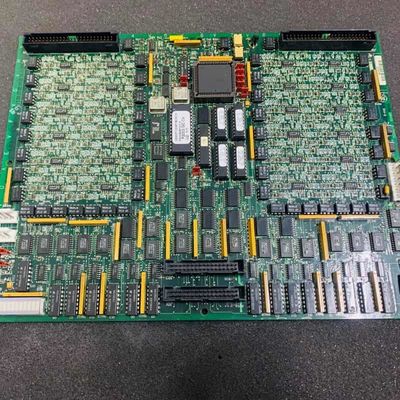

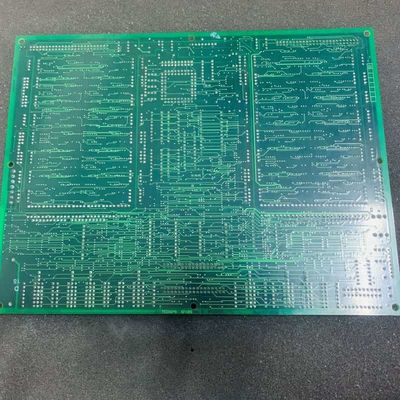

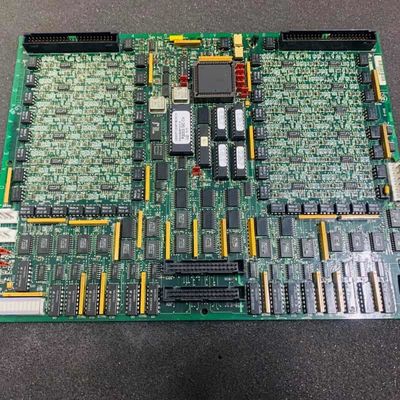

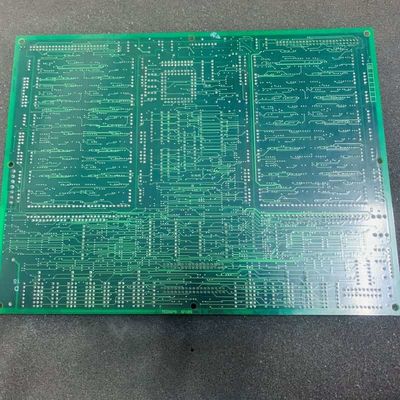

Papan I/O Digital GE DS200TCDAH1BGD dengan Penanganan Sinyal Analog Komprehensif Berat 2kg dan Garansi 1 tahun untuk Kontrol Turbin Mark V

| Nama | Ge ds200tcdah1bgd ds200tcdah1b Digital I/O Board | ID Produk | DS200TCDAH1B |

|---|---|---|---|

| Seri | Mark v | Fungsi | Paket keluaran diskrit |

| Kedalaman/panjang bersih produk | 330mm | Tinggi Net Produk | 200mm |

| Lebar Net Produk | 100mm | Bobot bersih produk | 2kg |

| Jaminan | 1 tahun | ||

| Menyoroti | Papan I/O Digital yang komprehensif untuk penanganan sinyal analog,Berat 2kg Papan GE Mark V,1 tahun Garansi Discrete Output Pack |

||

GE DS200TCDAH1BGD DS200TCDAH1B Digital I/O Board

Rincian produk:

GEDS200TCDAH1Badalah Digital I/O Board yang dirancang secara eksklusif untuk GE's Mark V Turbine Control System (Sistem Kontrol Turbin Mark V) seri lama yang digunakan untuk mengelola turbin angin, gas, dan uap,dan salah satu lini terakhir GE Mark untuk mengintegrasikan teknologi kontrol Speedtronic paten.

Secara fungsional, ia memproses sinyal analog yang beragam: masukan/keluar 4-20 mA melalui JBB/JAA, dengan arus turun melalui resistor beban untuk pembacaan tegangan, masukan RTD melalui JCC/JDD,memberikan rangsangan dan mengukur resistensi tergantung suhu, masukan termokopel melalui JAR/S/T, menggunakan kompensasi simpang dingin TBQA untuk menghitung suhu aktual, dan sinyal tegangan/arus poros turbin melalui JBB.Semua sinyal dikondisikan dikirim ke I / O Engine melalui konektor 3PL, dengan tipe termokopel konfigurasi perangkat lunak, pengaturan RTD dikelola melalui Editor Konfigurasi I/O HMI.

Fitur Utama:

Pengolahan sinyal analog yang komprehensif:Berfungsi sebagai pusat pusat untuk sinyal 4-20 mA, RTD, termokopel, dan skala tegangan/arus poros, pengkondisian, dan transmisi data ke Mesin I/O,kritis untuk pemantauan dan kontrol kinerja turbinIni memperbaiki sinyal mentah untuk menghilangkan kebisingan, memastikan data yang tepat yang membimbing penyesuaian real-time seperti aliran bahan bakar atau sistem pendinginan tweaks.

PROM yang bisa dilepas & sensitif ESD:Modul PROM yang dapat dilepas menyimpan firmware; menggantinya dengan perlindungan ESD seperti tali pergelangan tangan memastikan papan pengganti sesuai dengan fungsi asli dengan mempertahankan instruksi yang identik.Ini menghindari konfigurasi ulang firmware, mengurangi waktu pemeliharaan dan memastikan logika pemrosesan sinyal yang konsisten setelah penggantian.

Hardware & Software yang dapat dikonfigurasi:Tiga jumper (J1 / JP2 / JP3) menangani tweak perangkat keras, sementara pengaturan perangkat lunak menyesuaikan jenis termokopel / RTD dan parameter sinyal yang beradaptasi dengan beragam kebutuhan turbin.JP2 pengujian bantuan, dan perangkat lunak menyesuaikan untuk mencocokkan setup sensor turbin-spesifik dengan mulus.

Dedicated Component Interfacing:Sembilan konektor (delapan fungsional, satu vestigial) terhubung ke papan Mark V utama (TCPS, CTBA, TBCA, TBQA) untuk transmisi daya, data, dan sinyal diagnostik yang mulus, menghilangkan risiko percakapan silang.Tugas khusus setiap konektor memastikan sinyal mencapai target tanpa gangguan, meningkatkan stabilitas sistem.

Desain yang Berfokus pada Uji:Jumper (JP2/JP3) dan konektor khusus mendukung pengujian dan pemeliharaan pabrik, menyederhanakan pemecahan masalah sambil memastikan keandalan operasi normatif.JP2 menonaktifkan osilator untuk pengujian yang aman, dan konektor memungkinkan teknisi mengakses sinyal dengan mudah untuk mendiagnosis masalah dengan cepat.

![]()

![]()

| DS200DTBBG1ABB | DS200TCCAF1BDF |

| DS200SDCIG2AFB | IS200ISBBG1AAB |

| DS200SDCIG2AHB | IS200CABPG1BAA |

| DS200BDAAG1AAA | IS200DSFCG1AEB |

| DS200SIOBH1ABA | IS200DRLYH1BBB |